Influence of scanning velocity on Co24.7Cr5Mo5.4W alloy built via selective laser melting on roughness properties

Main Article Content

Abstract

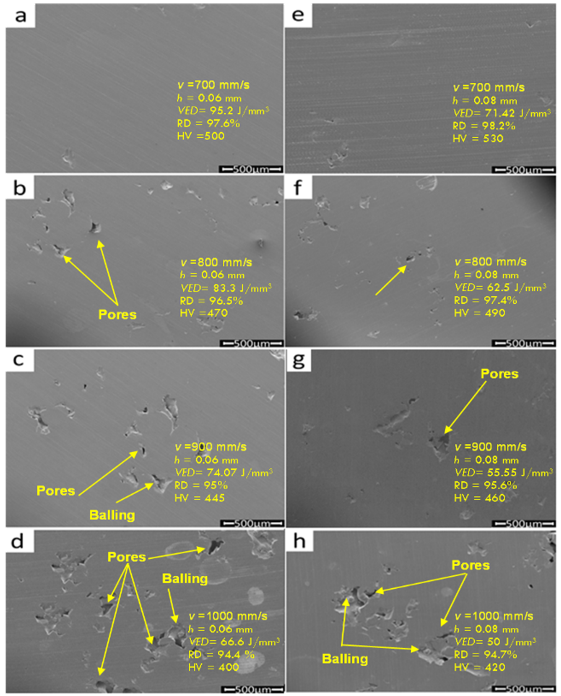

The utilization of Selective Laser Melting (SLM) in the production of intricate metal items has gained

significant attention in the medical and dental sectors. Products created using SLM must possess surfaces that exhibit

a high degree of smoothness. The objective of this research is to examine the impact of various laser process

parameters, specifically the scan rate and hatch spacing, on the surface roughness of Co-Cr dental alloys fabricated in

three dimensions (3D) by selective laser melting (SLM) technology. The results indicate that a scanning speed of 700

mm/s yields superior surface morphology and microstructure. The parameter investigation conducted in this paper

resulted in the attainment of relative densities as high as 98.9% for the additively built workpieces. The present study

focuses on investigating surface roughness in Co–Cr alloys fabricated using powder metallurgy techniques, namely

selective laser melting.

Received 4 Sept. 2023; Revised 18 Oct. 2023; Accepted 19 Oct. 2023; Published online 15 Jun. 2024

Corresponding Author: [email protected]