Effect of laser cleaning parameters on aluminum 6061 surface properties

Main Article Content

Abstract

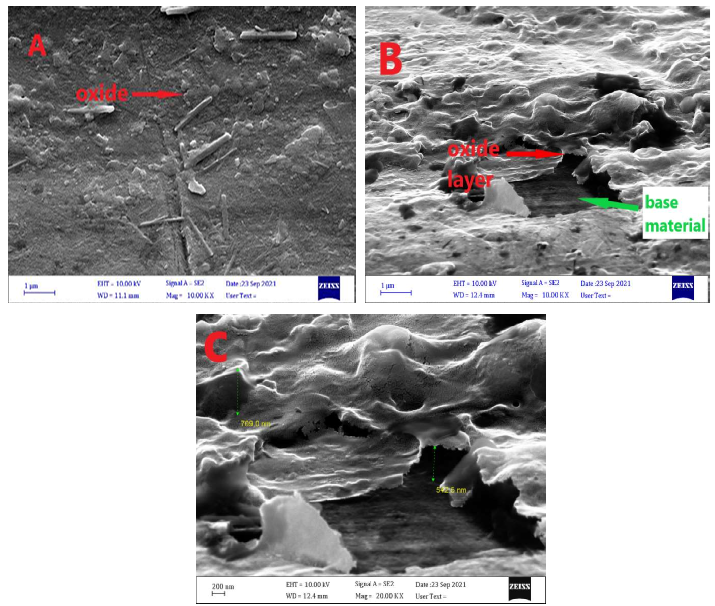

This study investigates the crucial factors influencing laser cleaning processes, with a primary focus on

aluminum 6061 surfaces. Laser power emerges as the central determinant, as higher power levels intensify the laser

matter interaction, leading to enhanced removal of oxide layers. A Microsecond fiber laser with a wavelength of 1064

nm was used in this study to identify optimal cleaning conditions, comprising parameters such as 3W power, a hatch

value of 0.003, a speed of 150 mm/s, and a spot size of 200 µm. Furthermore, the research uncovers intriguing insights

into the impact of cleaning speed on oxygen levels, revealing that higher speeds result in increased oxygen levels due

to dual heat sources—laser beam and heat transfer from adjacent cleaned lines. The hatch parameter's role is

highlighted in controlling the overlapping ratio, where closer line spacing leads to more effective cleaning and reduced

surface oxygen content, while wider line spacing impedes cleaning between lines. Additionally, the study explores

the potential enhancement of wear rates through laser cleaning, with material roughness playing a critical role, and

notes that cleaned samples exhibit fewer defects in their microstructure compared to their uncleaned counterparts.

These findings contribute valuable insights to the field of laser cleaning and its applications in surface treatment and

material quality improvement.

Received 4 Oct.2023; Revised 14 Nov. 2023;Accepted 14 Nov. 2023; Published online 15 Jun. 2024